Introduction

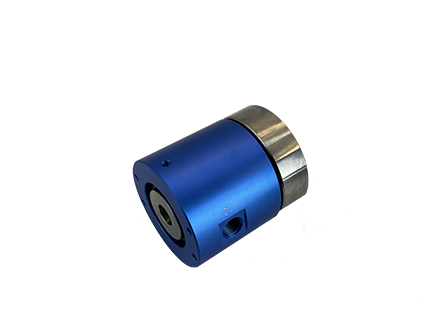

Die Luftpräzisions-Schleifring von Reehonde ist eine fortschrittliche Lösung für die reibungslose Übertragung von Energie und Daten zwischen rotierenden Geräteteilen. Sein einzigartiges Design eignet sich für hochpräzise Anwendungen, die eine stabile und zuverlässige Leistung in dynamischen Umgebungen erfordern. Ideal für den Einsatz in Industrien wie Luft- und Raumfahrt, Robotik, Telekommunikation und Medizingeräte Luftpräzisions-Schleifring gewährleistet einen kontinuierlichen Betrieb mit minimalem Verschleiß und bietet eine langlebige, leistungsstarke Verbindung in kritischen Systemen. Auch als Luftrutschringe oder Drehringe bekannt, bieten diese Geräte eine kontinuierliche Übertragung von elektrischen Signalen oder Leistung zwischen rotierenden und stationären Teilen, ideal für niedrige und hohe Geschwindigkeitsanwendungen.

Produktparameter

Arbeitsleben | Siehe die Tabelle zur Auswahl der Produktqualität | Nennspannung | 0-440VACNDC |

Nenndrehzahl | Siehe die Tabelle zur Auswahl der Produktqualität | Isolationsbeständigkeit | <500mq> |

Arbeitstemperatur | -30°C bis 80°C | Draht Spezifikation | AWG17#/AWG22#Silber beschichtetes Teflon |

Arbeitsfeuchtigkeit | 0 ~ 85% RXH | Drahtlänge | Standardlänge250mm |

Kontaktmaterial | Siehe die Tabelle zur Auswahl der Produktqualität | Isolationsfestigkeit | 500VAC@50XHz ,6S |

Schalenmaterial | Aluminiumlegierung | Dynamischer Widerstandsänderungswert | <0.010<> |

Rotation torque | 0.05N.m+0.02N.m/6Flow passage | Protection level | IP51 |

Key Features of the Luftpräzisions-Schleifring

High Precision Engineering: Die Luftpräzisions-Schleifring is designed with exceptional precision to ensure stable, high-quality signal and power transmission even in challenging conditions. It is built to minimize friction and reduce the risk of wear over time, ensuring consistent performance.

Durability and Longevity: Constructed from high-quality materials, the Luftpräzisions-Schleifring offers superior durability. It is engineered to withstand the test of time, even in environments with frequent rotational movement, extreme temperatures, or harsh operational conditions.

Minimal Contact Resistance: Die innovative design reduces the contact resistance to an extremely low level, resulting in enhanced signal integrity and reliable performance in data transfer applications.

High-Speed Capability: Die Luftpräzisions-Schleifring is capable of operating at high speeds without compromising functionality. It supports high rotational speeds and ensures uninterrupted data or power transmission.

Customizable Configurations: Reehonde offers a wide range of customizable options to meet the specific needs of your application. Whether you need specific power or data channels, specialized insulation materials, or particular sizes, our Luftpräzisions-Schleifring can be tailored to suit your requirements.

Compact Design: Die compact design allows for integration into a variety of devices without taking up too much space. This is especially important in applications where size and weight are crucial factors.

Versatile Applications: Die Luftpräzisions-Schleifring is versatile and is used in a broad spectrum of industries, including aerospace, robotics, medical, and telecommunications. It is designed to handle both power and signal transmission in environments where high precision and performance are necessary. It is also compatible with rotary unions that may require electrical connections alongside fluid transfer.

Installation Steps

Installing the Luftpräzisions-Schleifring, or rotary slip ring, is a straightforward process. However, it is important to follow the necessary guidelines to ensure proper setup and optimal performance. Here are the steps for installation:

Preparation: Ensure that you have all the necessary components, tools, and safety equipment before beginning the installation process. Confirm that the installation location is suitable for the Luftpräzisions-Schleifring.

Mounting the Slip Ring: Position the Luftpräzisions-Schleifring securely on the intended rotating device. It should be mounted on a fixed shaft or support to allow for smooth and controlled rotation. Ensure that the slip ring is aligned properly to prevent any misalignment during operation.

Wiring the Slip Ring: Connect the power and signal wires to the appropriate terminals on the slip ring. Make sure to follow the wiring diagram provided by Reehonde to ensure correct connections. Double-check all connections to avoid wiring errors that could compromise performance.

Testing Rotation: Once the slip ring is mounted and the wiring is complete, rotate the device manually to check for any obstructions or friction. If the rotation is smooth and uninterrupted, the installation is correct.

Power On: After testing the mechanical movement, power on the system to check the electrical and data connections. Monitor the slip ring during the initial test run to ensure that it is functioning as expected.

Secure the Connections: Once the system is verified, secure all electrical connections and ensure that there is no loose wiring. Tighten any fasteners to prevent movement during operation.

Final Inspection: Perform a final inspection to ensure that the slip ring is properly installed and all components are secure. Verify that the system is operating smoothly before proceeding with full-scale use.

Usage Notes and Precautions

Avoid Overloading: Do not exceed the rated current or power specifications of the Luftpräzisions-Schleifring. Overloading can cause excessive wear, overheating, and potential failure of the device.

Regular Maintenance: Regular maintenance is essential to ensure optimal performance. Periodically inspect the slip ring for signs of wear, corrosion, or damage. Clean the slip ring regularly to remove any dust or debris that may accumulate during operation.

Proper Lubrication: For slip rings that require lubrication, use the recommended lubricants as specified by Reehonde. Over-lubrication or using the wrong type of lubricant may lead to performance issues or failure.

Environmental Conditions: Ensure that the Luftpräzisions-Schleifring is used in environments within the specified temperature and humidity ranges. Extreme conditions outside these ranges can reduce the lifespan and performance of the device.

Avoid Vibration: While the Luftpräzisions-Schleifring is designed to handle rotational movement, excessive vibrations can affect performance. Ensure that the installation location minimizes vibrations that could impact the slip ring’s function.

Prevent Short Circuits: Always check for proper insulation and secure connections to avoid short circuits, which could damage the slip ring and other components in the system.

Handling and Storage: Handle the Luftpräzisions-Schleifring with care during installation and storage. Store the device in a dry, cool environment to prevent damage before installation.

Die Luftpräzisions-Schleifring by Reehonde represents a high-performance solution for applications requiring seamless power and data transmission in rotating systems. Whether referred to as an air slip ring, rotary slip ring, or rotary union, this device ensures optimal performance in applications requiring precision and durability. With its exceptional precision, minimal contact resistance, and versatile applications, it is an indispensable component for a wide range of industries. By following the installation guidelines and taking proper care of the product, you can ensure that your Luftpräzisions-Schleifring delivers reliable performance and long-lasting durability for years to come.